I. Isingeniso Se-Desulfurization Absorber

Umsebenzi oyinhloko we-absorption ye-desulfurization ukujikeleza nokufafaza udaka oluxutshwe ne-limestone ne-gypsum ngepompo ejikelezayo, kanye namapayipi ongqimba lwesifutho ukuze amunce i-sulfur dioxide ku-flue gas engena ku-absorber. I-sulfur dioxide emuncwa udaka isabela ne-limestone kanye komoya-mpilo ovuthela ku-absorber ukuze kukhiqizwe i-calcium sulfate dihydrate (gypsum), bese i-gypsum ekhiqiziwe ikhishelwa ohlelweni lokukhipha amanzi emzimbeni nge-gypsum discharge pump for dehydration.

II. Izindawo Ezintathu Ezisebenzayo ze-Desulfurization Absorber

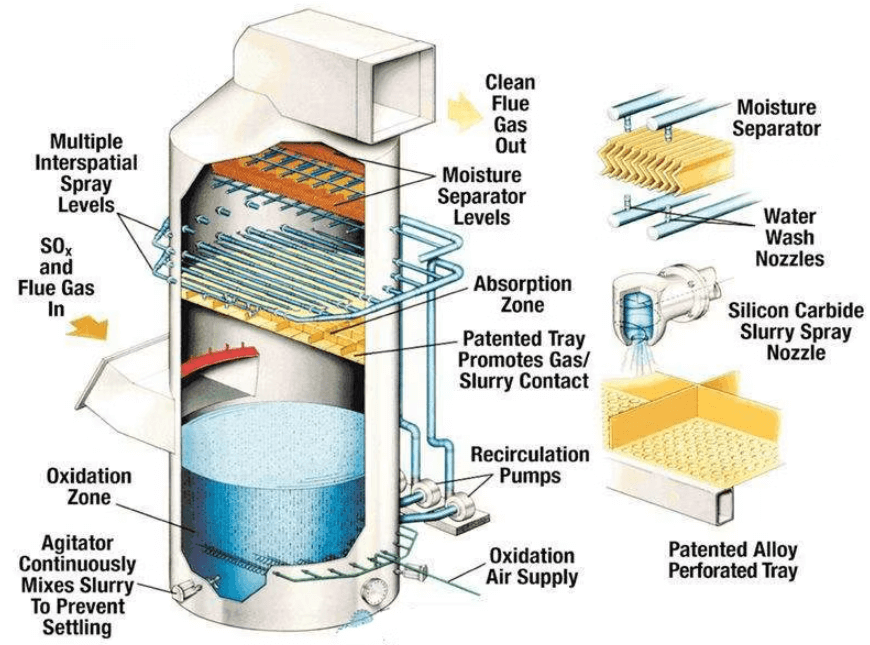

I-absorber ingahlukaniswa ezindaweni ezintathu zokusebenza ukusuka phezulu kuye phansi: i-oxidation crystallization, indawo yokumuncwa kanye ne-demisting.

(1) I-oxidation crystallization zone ibhekisela echibini elinodaka le-absorber, futhi umsebenzi walo oyinhloko ukuncibilikisa i-limestone kanye ne-oxidize calcium sulfite.

(2) Indawo yokumuncwa ihlanganisa indawo yokudonsa, ithreyi kanye nezingqimba ezimbalwa zezifutho. Kunezimbobo eziningi zekhoni ezingenalutho kungqimba ngalunye lwedivayisi yokufutha; umsebenzi oyinhloko we-absorber uncike ekungcoleni okune-asidi kanye nokumuncwa komlotha wempukane kugesi we-flue.

(3) Indawo yokukhipha ifaka ama-demister anezigaba ezimbili ngaphezulu kwesendlalelo sokufuthwa. Umsebenzi wawo oyinhloko ukuhlukanisa amaconsi kugesi we-flue, ukunciphisa umthelela kumishini engaphansi komfula kanye nomthamo wokumunca.

Indawo yokumunca yesibambo ibhekisela endaweni ephakathi komugqa ophakathi nendawo yokungena kwesinqamuleli kanye naleyo yongqimba oluphakeme kakhulu lwesifutho. I-slurry efuthiwe igeza igesi ye-flue enesulfure kule ndawo. Ukuphakama okwanele kwendawo yokumunca kuqinisekisa izinga eliphezulu le-desulfurization. Ukuphakama kokuphakama, kuyancipha izinga lokugeleza kwephampu ejikelezayo edingekayo Ngaphansi kwemfuneko efanayo yezinga le-desulfurization.

I-spray zone ye-absorber ichazwa ngokuthi:

(1) Isifutho sombhoshongo: 1.5m ngaphansi kombhobho ophansi kakhulu ukuya endaweni yokuphuma yombobho ophakeme kakhulu.

(2) Umbhoshongo wekholomu yoketshezi: ukusuka lapho kuphuma khona umlomo wombhobho ophansi kakhulu ukuya ku-0.5m ngaphezu kwekholomu ephakeme kakhulu yoketshezi lapho wonke amaphampu ajikelezayo odaka esebenza.

I-absorber iyisisetshenziswa esiyinhloko sesistimu ye-flue gas desulfurization. Idinga indawo enkulu yokuthintana noketshezi lwegesi, ukusabela okuhle kokumuncwa kwegesi, ukulahlekelwa kwengcindezi encane. Ilungele ukulashwa kwegesi yomkhuhlane omkhulu. Izinyathelo zenqubo eziyinhloko ezilandelayo ziqedwa kule divayisi:

① Ukumuncwa kwamagesi ayingozi ekugezeni okudaka;

② Ukuhlukaniswa kwegesi ephumayo kanye nodaka lokuwasha;

③ Neutralization of slurry;

④ Ukufakwa kwe-oxidation kwemikhiqizo yokungathathi hlangothi emaphakathi ibe yi-gypsum;

⑤ I-Gypsum crystallization.

III. Ukwakheka kwe-Absorber

I-absorber ngokuvamile ihlukaniswa ibe isilinda, i-flue gas inlet kanye ne-flue gas outlet ngesakhiwo. I-flue gas inlet kanye ne-outlet ilele phakathi nendawo yokudonsa futhi phezulu kwesibambisi ngokuhambisanayo ngokujwayelekile. I-absorber cylinder ingahlukaniswa ibe i-slurry pool, isendlalelo sesifutho kanye nendawo yokuqeda ukusebenza. I-slurry pool itholakala engxenyeni engezansi ye-absorber inlet ngokuvamile, futhi isendlalelo sesifutho kanye ne-demister zitholakala phakathi kwe-flue gas inlet kanye ne-outlet. I-flue gas outlet ye-absorber ingaba i-outlet eqondile ephezulu noma i-outlet eseceleni evundlile.

Indawo yesifutho evamile ifaka izendlalelo zesifutho namabhobho kanye nezinye izinto. Ngokuya ngenqubo ye-desulfurization, indawo yesifutho yamanye ama-absorber izophinde ifakwe amathreyi, izinduku ze-Venturi namanye amadivaysi.

IV. Izidingo zedizayini ze-Absorber

(1) Isilinganiso se-calcium-sulphur akufanele sibe ngaphezu kuka-1.05.

(2) Uma usebenzisa i-in-tower demister, isivinini segesi ephehlwayo yesixhumi ngaphansi kwezimo zokuklama akufanele sidlule u-3.8m/s, esingagadwa Coriuwoyelasfphansiwahlanganaer.

(3) Isakhiwo esihlanganisiwe sechibi elinodaka kanye nomzimba wombhoshongo kuyakhethwa.

(4) Isikhathi sokuhlala sokujikeleza kwe-slurry akufanele sibe ngaphansi kwamaminithi angu-4, futhi umbhoshongo wekholomu yoketshezi akufanele ube ngaphansi kwamaminithi angu-2.5.

(5) Iringi egcina amanzi kanye nekhava yemvula kufanele kufakwe ezimpambanweni zombhobho wokungenisa amanzi kanye nodonga olume mpo lwesibambisi.

(6) I-inlet flue yombhoshongo ongenalutho wesifutho kufanele uhlelwe ngendlela yokungena etshekile eya phansi. Lapho kwamukelwa ukuhlelwa kokungena okuvundlile, kufanele kuqinisekiswe ukuthi indawo ephansi kakhulu yombhobho endololwaneni yokuqala eseduze nendawo yokudonsa i-absorber ingu-1.5 kuya ku-2m ngaphezu kwezinga elivamile le-liquid elisebenzayo le-absorber slurry pool. I-inlet flue yombhoshongo wekholomu ye-liquid ingahlelwa ngendlela yokungena evundlile noma eqondile.

(7) Ibanga phakathi kwezingqimba eziseduze zesifutho zombhoshongo ongenalutho wesifutho akufanele libe ngaphansi kuka-1.8m.

(8) Ungqimba olungaphezulu lwesifutho lombhoshongo wokufutha ongenalutho kufanele lufuthwe luye phansi kuphela, futhi ibanga lenethi ukusuka kungqimba oluphansi kakhulu lwe-demister akufanele libe ngaphansi kwama-2m.

(9) Emibhoshongweni yesifutho efakwe amathreyi anezimbotshana namathebula, amathreyi anezimbotshana nama-tabulator kufanele enziwe ngezinto ezilwa nokugqwala kwengxubevange.

(10) Uma idivayisi yokushisisa igesi yokukhipha umoya neyokushintshanisa ukushisa ingafakiwe, ukukhethwa kwemingcele yedizayini efana nenani lokugeleza kombhoshongo ongenalutho, isilinganiso segesi ewuketshezi, nokuqukethwe okuqinile kodaka lwesibambo kufanele kucabangele izimfuneko zokusebenza kahle kwe-desulfurization kanye nomthelela wezinto ezinjengokunciphisa inani lamaconsi egesi ephuma emanzini aphethwe.

(11) Idizayini yesibambisi kufanele ihambisane nohlu lwedizayini yomthamo wobhayela kanye nokuqukethwe kwesibabule samalahle. Umuntu ohlakaniphileokungezona zenuzii-slurry density meterkusukaI-LonnmeterKunconywa ukuthi kuqashwe ukuminyana kwe-limestone kanye ne-gypsum endaweni yokudayisa ukuze kuqinisekiswe izinga elanele le-desulfurization.

Isikhathi sokuthumela: Feb-05-2025