Ukukhiqizwa kweingilazi yamanzi ye-sodium silicateifuna ukulawula okucophelelayoukugxila emgqeniyezingxenye ezibalulekile ezifanaNa2O,K2O, futhiSiO2ukuqinisekisa ikhwalithi yomkhiqizo engaguquki kanye nokusebenza kahle. Amathuluzi athuthukile afanaamamitha okuhlushwa usawoti,amamitha wokuhlushwa we-silica sand, futhiamamitha okuhlushwavumelaamanzi ingilazi sodium silicate abahlinzekiukuqapha nokulungisa le mingcele ngesikhathi sangempela, ukunciphisa ukuchezuka nokuthuthukisa izindleko.

Technical Know-How and Chemical Process

Ukwenziwa kweingilazi yamanzi ye-sodium silicate, inhlanganisela ehlukahlukene ehlanganisa izimboni ezifana nezokwakha, izindwangu, nezimayini, idinga ukunemba kuzo zonke izigaba. Inqubo iqala ngokuhlanganiswa kokuhlanzeka okuphezuluisihlabathi se-silica (SiO2)kanye ne-alkali carbonates, njenge-sodium carbonate (Na2CO3) noma i-potassium carbonate (K2CO3), emazingeni okushisa asukela ku-1200°C kuya ku-1500°C, okulandelwa ukuhlakazwa kwama-autoclave nokuhlunga ukuze kukhishwe ukungcola. Ngisho nokuguquguquka okuncane kuUkugxila kwe-Na2OnomaUkugxila kwe-SiO2ingafaka engcupheni i-viscosity, ukuminyana, noma ubumsulwa, okuholela ekusebenzeni komkhiqizo okungahambisani.

Kungani Ukunemba Ekuqapheni Ukugxila Kubalulekile

Ukukhiqizwa kwengilazi yamanzi ye-sodium silicate kuncike ekugcineni ibhalansi ncamashi yezinto zokusetshenziswa, njengoba isilinganiso sokugxiliswa kwe-SiO2 kanye nokugxila kwe-Na2O kuthonya ngokuqondile izici zokunamathela zomkhiqizo, i-viscosity, nokuzinza kwamakhemikhali. Phakathi nesigaba sokuncibilika kwezinga lokushisa eliphezulu, lapho isihlabathi se-silica sihlanganiswa ne-alkali carbonates, noma isigaba sokuhlakazeka kuma-autoclave asebenza ku-4-5 bar kanye no-140-150 ° C, ngisho nokuphambuka okuncane ekubunjweni kungaphazamisa inqubo. Amamitha okugxilisa asemgqeni athuthukile, avame ukubizwa ngokuthi amamitha okugxilisa usawoti esihlabathini se-silica, ahlinzeka ngokuqapha okuqhubekayo kwalezi zingxenye ezibalulekile, okuvumela abakhiqizi ukuthi bathole futhi balungise izinkinga ngokushesha, ngaleyo ndlela baqinisekise ikhwalithi yomkhiqizo engaguquki.

Izinzuzo zokulinganisa okuqondile okusemgqeni kudlulela ngale kokuqinisekiswa kwekhwalithi. Ngokugcina izilinganiso ezilungile ze-alkali-to-silica, abakhiqizi banganciphisa ukumosha, banciphise ukusetshenziswa kwamandla, futhi baqinisekise ukuthobela imithetho eqinile yezimboni.

Izingozi Zokukala Okungaguquki Nenganembile

Ngaphandle kokulinganisa okuqinile okuphakathi komugqa, abakhiqizi babhekana nezinselele ezinkulu ezingahlehlisa ukusebenza kwabo. Izinguquko ku-Na2Ukugxila kwe-O kungaholela emikhiqizweni esebenza ngokungathembeki, njengezinamatheliso ezibuthakathaka noma ama-sealant angahambisani. Ukwengeza, amaqoqo angacacisiwe adinga ukusetshenzwa kabusha okumba eqolo noma ukulahlwa, okwandisa izindleko zokukhiqiza.

Ukuthatha amasampula okwenziwa ngesandla, uma kuqhathaniswa namamitha okugxilisa asemgqeni wesimanje, kudla isikhathi futhi kujwayele ukuba namaphutha, okuholela ekubambezelekeni kwenqubo kanye nezindleko eziphezulu zomsebenzi. Ngaphezu kwalokho, ukwehluleka ukuhlangabezana namazinga okulawula okuhlanzeka kungaholela ezijezisweni noma ezinkontilekeni ezilahlekile, ikakhulukazi ezicelweni zokuhlanzeka okuphezulu njengezindwangu noma izitsha zobumba. Ngokuhlanganisa amamitha okugxilisa usawoti kanye namamitha okugxilisa isihlabathi se-silica, abahlinzeki bengilazi yamanzi be-sodium silicate banganciphisa lezi zingozi, baqinisekise inqubo yokukhiqiza ehlelekile nengabizi.

Amathuluzi Okulinganisa Okuphumelelayo Kwe-Inline Concentration

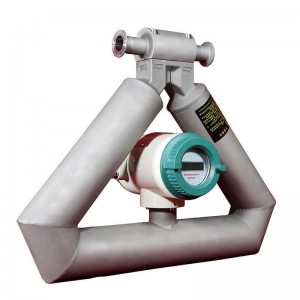

Imitha yokuhlushwa ye-ultrasonic nge-Lonnmeter iyimitha ye-non-nuclear density eklanyelwe ngokuqondile ukuminyana kwesikhathi sangempela kanye nesilinganiso sokuhlushwa kuma-slurries nolunye uketshezi, okwenza kube kufaneleka kakhulu ezimweni ezinzima zokukhiqiza ingilazi yamanzi.

Ngokungafani namamitha avamile we-nuclear density, le divayisi isebenzisa ubuchwepheshe be-ultrasonic obuphephile, obungeyona imisebe, obukala isikhathi sokudluliswa kwamagagasi omsindo ukusuka emthonjeni wesignali ukuya kumamukeli wesignali ukuze kubonwe isivinini somsindo, bese, ngokulandelayo, ukuminyana nokugxila koketshezi.

Le ndlela ayithintwa ukuqhutshwa koketshezi, umbala, noma ukukhanya, okuqinisekisa ukuthembeka okuphezulu kakhulu nokunemba, nabasebenzisi bathola ukunemba kokulinganisa kokungu-0.05% kuya ku-0.1%. Lokhu kunemba kubalulekile ukuze kugcinwe isilinganiso esinembile se-alkali-to-silica esidingekayo ekukhiqizweni kwengilazi yamanzi, ukuqinisekisa ikhwalithi yomkhiqizo engaguquki.

Ukukhetha I-Concentration Meter Elungile Yezidingo Zakho

Ukukhetha imitha yokugxilisa efanele kudinga ukucatshangelwa ngokucophelela kwezici ezimbalwa. Isigaba esithile sokukhiqiza, esifana nokuncibilika noma ukuchithwa kwe-autoclave, sinquma ukuthi amamitha okugxilisa usawoti noma amamitha okugxilisa isihlabathi se-silica afaneleka kakhulu. Imikhawulo yesabelomali nayo idlala indima, njengoba amamitha okugxilisa ingqondo ajwayelekile enikeza ukusebenza okubanzi kodwa eza nezindleko eziphezulu. Kuzinhlelo zokusebenza ezidinga ukuhlanzeka okukhethekile, njengokucutshungulwa kwezindwangu, ukukala okunemba okuphezulu kwe-SiO2 kubalulekile, kudinga izinzwa ezithuthukile. Ukwengeza, ukuhambisana nezinhlelo ezikhona zokulawula inqubo kuqinisekisa ukuhlanganiswa okungenamthungo kanye nokusetshenziswa kwedatha. Ngokuhlola lezi zici, abahlinzeki bengilazi ye-sodium silicate yengilazi yamanzi bangatshala kumamitha okugxilisa asemgqeni ahambisana nezinhloso zabo zokusebenza, athuthukise ikhwalithi yomkhiqizo nokusebenza kahle.

Ukuhlanganisa Amamitha Okugxilisa ingqondo Ekuhambeni komsebenzi Wokukhiqiza

Ukuze basebenzise ngokugcwele amandla amamitha okugxilisa asemgqeni, abakhiqizi kufanele bahlanganise la mathuluzi ezinhlelweni zabo zokukhiqiza. Ukubeka amamitha okugxilisa isihlabathi se-silica ethangini elincibilikayo namamitha okugxilisa usawoti ku-autoclave kuqinisekisa ukuqapha okuphelele kuzo zonke izigaba ezibalulekile.

Ukukhipha amasistimu angasasebenzi kunciphisa isikhathi sokuphumula ngesikhathi sokulungiswa, kugcina ukusebenza okuqhubekayo. Ngokusebenzisa ama-analytics avela kulawa mamitha, abahlinzeki bengilazi ye-sodium silicate yengilazi yamanzi bangakwazi ukwandisa izilinganiso zezinto ezingavuthiwe, banciphise ukungcola, futhi bathuthukise ukusebenza kahle sekukonke.

Imibuzo Evame Ukubuzwa

Amamitha Okugxilisa Usawoti Ayithuthukisa Kanjani Ikhwalithi Yengilazi Yamanzi?

Amamitha okugxilisa usawoti ahlinzeka ngokuqapha kwesikhathi sangempela kokugxiliswa kwe-Na2O nokugxiliswa kwe-K2O, ukuqinisekisa ukuthi isilinganiso se-alkali-to-silica sihlala silingana. Lokhu kunemba kuvimbela ukuhlukahluka kwe-viscosity kanye nokuminyana, iletha ingilazi yamanzi ye-sodium silicate enokwethenjelwa ukuze isetshenziswe njengama-adhesives nama-detergents, okuthuthukisa ikhwalithi yomkhiqizo jikelele.

Iyiphi Indima Edlalwa I-Silica Sand Concentration Meters?

Amamitha okugxilisa isihlabathi se-silica abalulekile esilinganisweni esinembile se-SiO2 phakathi nesigaba sokuncibilika, okuqinisekisa ukuthi okuqukethwe kwe-silica kuhambisana nokucaciswa. Lokhu kugcina ukucaca namandla engilazi yamanzi ye-sodium silicate, okubalulekile ekusetshenzisweni kokuhlanzeka okuphezulu njengezindwangu nezitsha zobumba.

Ingabe I-Inline Concentration Meters Angazinciphisa Izindleko Zokukhiqiza?

Ngokunciphisa ama-off-spec batches, ukwandisa ukusetshenziswa kwempahla eluhlaza, nokuqapha okuzenzakalelayo, amamitha okugxilisa asemgqeni njengamamitha okugxilisa usawoti kanye namamitha okugxilisa isihlabathi se-silica kunciphisa kakhulu izindleko zokukhiqiza. Abahlinzeki bengilazi ye-sodium silicate yengilazi yamanzi bayahlomula ekumosheni okuphansi kanye nezindleko zabasebenzi, okwenza inzuzo.

Ukulawula okunembile kweUkugxila kwe-Na2O,Ukugxila kwe-K2O, futhiUkugxila kwe-SiO2ibalulekile ekukhiqizeni izinga eliphezuluingilazi yamanzi ye-sodium silicateehlangabezana nezidingo zezimboni ezifana nezokwakha, izindwangu, nezimayini.

Ngokwamukela lobu buchwepheshe nezinqubo ezingcono kakhulu, abakhiqizi bangakwazi ukwenza lula ukusebenza futhi balethe imikhiqizo ephezulu. Ulungele ukuphakamisa ukukhiqizwa kwakho kwengilazi yamanzi?Xhumana nethimba lethuukuhlola okuthuthukileamamitha okuhlushwayakhelwe izidingo zakho futhi uvule amandla aphelele enqubo yakho yokukhiqiza.

Isikhathi sokuthumela: Jun-26-2025