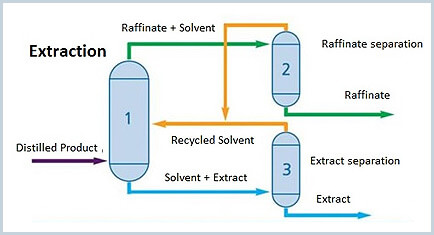

Enqubweni eyinkimbinkimbi yokugeleza kwe-lubricating oil solvent refining, ukulawula ukuminyana kuhamba kuyo yonke inquboukulinganisa ukuminyana kwamafutha okugcoba. Umgomo wokukhipha usetshenziselwa ukuhlukanisa izingxenye ezingafanelekile kusuka kumafrakshini kawoyela wokugcoba. Le ndlela isebenzisa izincibilikisi ezifana ne-furfural kanye ne-phenol ukuze kuzuzwe ukukhishwa kwesigaba se-liquid ngaphansi kwezimo ezithile zokushisa, ikakhulukazi ukususa ama-hydrocarbon e-polycyclic short-side-chain hydrocarbons kanye ne-sulphur/nitrogen-containing compounds.

Isigaba sokuncibilikisa okucebile esiqukethe izingxenye ezingafanelekile kanye nesigaba sikawoyela ocwenge kakhulu uma kuqhathaniswa sibhekana nokuhlukaniswa kokuqala kukholamu yokukhipha, ephuma ezitolo ezihlukene ngokulandelana. Isigaba se-solvent esicebile singena ohlelweni lokubuyisela i-solvent, lapho i-solvent ivuselelwa kabusha nge-distillation nezinye izindlela; isigaba samafutha acwengisisiwe singena ezinqubweni ezilandelayo ezifana nokuhlubula nokomisa ukuze kuqhutshekwe nokususa izincibilikisi ezisele, ukuthola uwoyela wesisekelo samafutha ocolisisiwe oqeqeshiwe.

Imiphumela Yamaphutha Esilinganiso Sokuminyana

Izinsalela Ezeqile Zezingxenye Ezingezona Ezinhle

Uma ukulawulwa kokuminyana endaweni yokuphuma kwamafutha acwengisisiwe kuphezulu kakhulu, izinsalela zezingxenye ezingafanelekile zizodlula izinga, zinciphise kakhulu ukumelana ne-oxidation kanye nokuzinza kokushisa kwamafutha okugcoba. Lokhu kuzodala inkomba ye-viscosity engavamile, yehluleke ukuhlangabezana nezidingo zezimo zokusebenza, futhi kungase kuholele ngisho nasekugqwaleni kwemishini kanye nezindaba zokuvikelwa kwemvelo ngenxa yezinsalela ze-solvent.

Ingozi Yezinsalela Ze-Solvent

Ukulawula ukuminyana okunganembile kungase kubangele ukukhishwa okungaphelele kwezincibilikizo (ezifana ne-furfural) emafutheni acwengisisiwe. Izinsalela ze-solvent zizogqwala izingxenye zensimbi. Ikakhulukazi emikhakheni enembayo ephezulu njengowoyela wokuthambisa wendiza, angabangela izingozi ezingathi sína zokuphepha njengokuguga kophawu nokugqwala.

Ukwehluleka Okuvamile Kusistimu Yokubuyisela I-Solvent

Ukuminyana okungavamile endaweni yokuncibilikisa okucebile kuzoholela ekuhlanzekeni kwengxenye encishisiwe, kwenze buthaka umthamo we-solvent, futhi kwakhe umjikelezo ononya. Ukuqoqwa kwamanzi kuzodala i-emulsification ye-solvent, edinga ukwelashwa okwengeziwe. Ukungcola okungena ohlelweni kuzophinde kuvimbele okokusebenza, izakhi zokugqoka, futhi kukhuphule izindleko zokulungisa kanye nesikhathi sokuphumula.

Inkinga Yezinzuzo Zezomnotho Nokuthobelana

Ukulawula ukuminyana okungalungile kuzokhuphula izindleko ezifana nokusebenza kabusha komkhiqizo, imfucuza encibilikayo, nokugcinwa kwemishini, futhi kungase kuholele ezijezisweni noma ngisho nokumiswa nokulungiswa kokukhiqiza ngenxa yokungathobeli imithetho yemvelo.

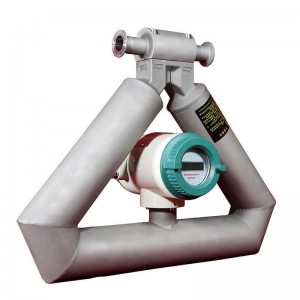

Isizinda Sekholomu/Isistimu Yokubuyisela I-Solvent

Enqubweni yokucwenga i-solvent kawoyela yokugcoba, ikholomu yokukhipha kanye nesistimu yokubuyisela i-solvent yizixhumanisi eziyinhloko. Ukuqapha okunembile nokulawulwa kwamapharamitha wokuminyana kuthinta ngokuqondile ikhwalithi yomkhiqizo, ukusebenza kahle kokukhiqiza, nokuphepha. Njengethuluzi lokuqapha lesikhathi sangempela, imitha yokuminyana emgqeni ingafinyelela ukuthuthukiswa okuguquguqukayo kwemingcele yenqubo ebalulekile ngokuqhubeka nokuqoqa idatha yokuminyana koketshezi futhi ixhumanise nesistimu yokulawula. amamitha okuminyana emgqeni ngokuvamile afakwa epayipini lokuphuma likawoyela acwengisisiwe phezulu kwekholomu kanye nepayipi lokuphuma le-solvent ecebile ngaphansi kwekholomu.

Imisebenzi esemqoka yamamitha okuminyana okusemgqeni

Ukulungiswa Kwe-Dynamic kwe-Solvent Ratio

Uma ukuminyana kwamafutha acwengekile phezulu kwekholomu kuphezulu kakhulu (ngezingxenye ezisele ezingezona ezifanelekile), umthamo womjovo we-solvent uzokwengezwa ngokuzenzakalelayo ukuze kuthuthukiswe ukusebenza kahle kokukhipha; uma ukuminyana kuphansi kakhulu (nge-solvent eyeqile), ukusetshenziswa kwe-solvent kuzoncishiswa ukuze kugwenywe imfucuza.

Isexwayiso Sangaphambi kwesikhathi Sokungajwayelekile Kokuhlukaniswa Kwesigaba

Uma "ukukhukhula" noma "umzila" kwenzeka kukholomu yokukhipha, idatha ye-densitometer izoshintshashintsha kakhulu, futhi isistimu ingakhipha ama-alamu ngesikhathi futhi ilungise amapharamitha okusebenza (njengezinga lokugeleza nezinga lokushisa) ukuze kuvinjelwe izingozi zokukhiqiza.

Ukuthuthukiswa Komthwalo Wekholomu Wokukhipha

Ngokuqhubeka nokuqapha idatha yokuminyana, ukugeleza kokubalulekile kukholamu kuyalinganiswa ukuze kugwenywe ukugcwala kwendawo okubangelwa ukuminyana okungalingani futhi kunwetshwe umjikelezo wokusebenza kwesisetshenziswa.

Izinzuzo ze-Lonnmeter Inline Density Meters

I-Lonnmeteramamitha wokuminyana emgqeniziye zagqama phakathi kwemikhiqizo embonini efanayo ngokusebenza kwazo okuqinile nokuzivumelanisa nezimo okuhle kakhulu ngemva kwamashumi eminyaka okuqinisekiswa kwemakethe, zinikeza izixazululo ezinokwethenjelwa zokuqapha ukuminyana koketshezi ezimbonini ezihlukahlukene. Amakhasimende angakhetha amamitha okuminyana asemgqeni ngokunemba okuhlukile ngokuya ngezimo ezithile zokusebenza.

Mayelana nokunemba, amamitha okuminyana asemgqeni we-Lonnmeter afinyelele izinga eliphezulu embonini, namanye amamodeli azuze ukunemba okungu-±0.0005 g/cm³, okwedlula kude izinga elimaphakathi lemikhiqizo efanayo. Amakhasimende angakwazi ukukhetha imikhiqizo enamaleveli ahlukene anemba ngokuya ngezimo ezithile zokusebenza, kusukela kokuyisisekelo okungu-±0.01 g/cm³ ukuya kokunemba okuphezulu okungu-±0.0005 g/cm³, ukuze athole ibhalansi engcono kakhulu phakathi kwezindleko nokusebenza.

Kwemithombo yezindaba eqala ukugqwala, i-Lonnmeter ihlinzeka ngezinto ezihlukahlukene ezimelana nokugqwala, okuhlanganisa i-Hastelloy, i-titanium alloy, ne-polytetrafluoroethylene, engamelana nokuguguleka kwesikhathi eside kwemidiya egqwalayo eqinile njenge-hydrochloric acid ne-sulfuric acid, enweba kakhulu impilo yesevisi yemishini nokunciphisa izindleko zokuyilungisa.

I-Lonnmeter inline density metres asekela izindlela zokufaka eziningi, okuhlanganisa ukukhwezwa ezinhlangothini, okubekwe phezulu, nokufakwe ngamapayipi, akwazi ukuzivumelanisa ngokuphelele nesakhiwo semishini namapayipi ahlukahlukene. Ngasikhathi sinye, ahlomeke nge-interface yedatha ecebile njenge-4-20mA, RS485, ne-Modbus, engaxhunywa ngaphandle komthungo ezinhlelweni zokulawula ezifana ne-DCS ne-PLC ukuze kuzuzwe ukuqapha okukude nokulawula okuzenzakalelayo, ukusiza amabhizinisi ukuthuthukisa ukusebenza kahle kokukhiqiza namazinga obuhlakani.

Emkhakheni wokukhipha uwoyela wokugcoba, ukuqapha okunembile kokuminyana kuyisihluthulelo sokuthuthukisa ikhwalithi yomkhiqizo nokusebenza kahle kokukhiqiza. I-Lonnmeter inline density metres isize amabhizinisi amaningi ukuba afinyelele ukukhiqiza okuphumelelayo ngezinzuzo zawo eziningi.

Uma futhi ufuna isixazululo esinokwethenjelwa sokulinganisa ukuminyana, wamukelekile ukuthatha isinyathelo manje! Chofoza ukuze uqalise uphenyo ukuze uthole ikhathalogi yomkhiqizo enemininingwane yamahhala yamamitha aphakathi komugqa we-Lonnmeter wokuminyana, amboze uhla olugcwele lwamapharamitha womkhiqizo ngokunemba okuhlukile nezinto ezisetshenziswayo ukukusiza ukuthi ukhethe ngokushesha imodeli efanele; ungaphinda uvule amacala amakhasimende acebile embonini yokukhipha uwoyela wokuthambisa ukuze uqonde ngokujulile ukuthi sizixazulula kanjani izinkinga zokuqapha ukuminyana kwamabhizinisi futhi sizuze ukuncipha kwezindleko kanye nokwenza ngcono ukusebenza kahle.

Isikhathi sokuthumela: Jun-05-2025