Isilinganiso se-viscosity se-polymer sinquma inqubo yokukhipha kanye nokubumba. Ukuqapha kwe-viscosity ngesikhathi sangempela kubaluleke kakhulu kunokuqapha izinga lokushisa nokucindezela.

Overviawuof ExtrusunMoldingProcess

Ukubumba i-Extrusion kuyinqubo yokukhiqiza ephumelelayo ezimbonini eziningi ukuze kukhiqizwe amaphrofayili aqhubekayo njengamapayipi, amafilimu, amashidi, njll. Ivumela ukukhiqizwa kobumo obuyinkimbinkimbi bezigaba ezihlukene ngekhwalithi engaguquki kuyilapho kuqinisekisa isivinini esikhulu sokukhiqiza nokusebenza kahle kwempahla. Intuthuko esobala efana nenqubo yokuzenzakalela, ukuqapha kwesikhathi sangempela kanye nokuqapha inqubo yokugaywa kabusha kuthuthukise ukunemba kwanciphisa umthelela wendawo ngokuncishiswa kwemfucuza.

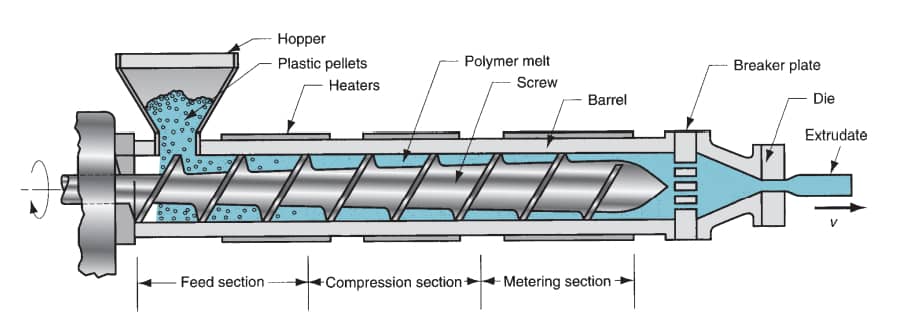

I-Rough Idea kweExtrusikuMachine

Umshini we-extrusion uqukethe izingxenye ezilandelayo: i-hopper, isikulufu sokudla, izinto zokufudumeza kanye nephampu yegiya. Impahla ifakwa emshinini ku-hopper. Isikulufu sokuphakelayo esijikelezayo ngokuqhubekayo, esishayelwa injini kanye nebhokisi legiya, sinyakazisa impahla emgqonyeni kanye nangedayizi. Izinto ezishisisayo eduze komgqomo zigcina amazinga okushisa alawulwayo ukuze athambise futhi ancibilike i-polymer material. Ngemva kokuphuma endaweni encibilikisiwe, into encibilikisiwe ingena esikhunjeni esinomgodi owodwa noma ngaphezulu, lapho ipholisa khona futhi iqine ibe yisimo esifisayo. Kwamanye amasistimu, iphampu yegiya ibekwa phakathi komgqomo futhi ife ukuze kuqinisekiswe ingcindezi engaguquki kokokusebenza okuphumayo.

Amaphuzu Abalulekile Wokulinganisa I-Viscosity Emshinini Wokukhipha

Ukuphuma kwe-Hopper / Indawo Yokuphakelayo: Ikala i-viscosity yokuqala yokuncibilika njengoba i-polymer iqala ukuthamba.

I-Melting Zone (Mid-Barrel): Ithwebula inguquko iye esimweni sokuncibilika ngokuphelele.

I-Metering Zone(Ngaphambi Kwephampu Yegiya noma I-Die): Ikala ukulinganiswa kwe-viscosity ye-polymer ngaphansi kwamazinga okusebenza okugunda.

I-Die Entrance: Inikeza idatha ye-viscosity yesikhathi sangempela endaweni yokukhishwa.

Ukuqonda i-Polymer Melt kanye ne-viscosity

Iyini i-polymer melt?

Kuyi-polymer eshiselwe esimweni esincibilikisiwe, ekhombisa izakhiwo zokugeleza ezivumela ukubunjwa nge-extrusion noma ukubumba. Incibilikisa i-viscosity yama-polymers-ukumelana nokugeleza-kuncike esisindweni samangqamuzana, izinga lokushisa, izinga lokugunda, nezithasiselo, okuthonya amandla nokuphela komkhiqizo wokugcina. Kweinqubo ye-polymer extrusion, lapho i-polymer encibilikisiwe ikhishwa ngomshini wokufa, futhi ekubunjweni komjovo, lapho igcwalisa khona isikhunta ngaphansi kwengcindezi, igcine izinga eliphezuluncibilikisa i-viscositykubalulekile. Yendabukoi-polymer melt viscosity isilinganisoIzindlela, njenge-off-line capillary rheometry, imvamisa ibambezeleka ngenxa yokubambezeleka, okuholela ekushintsheniemugqenii-viscometer yama-polymersukuze uthole imininingwane yesikhathi sangempela.

Izinselelo ku-Polymer Extrusion kanye Nokulawulwa Kwenqubo

Iinqubo ye-polymer extrusionnokubumba umjovo kubhekana nezithiyo ezibalulekile ekugcineni kungaguqukincibilikisa i-viscosity. Ukuhlukahluka ngenxa ye-gradient eshisayo kanye namazinga okugunda okuguquguqukayo kungaholela ekungalinganinincibilikisa i-viscosity yama-polymers, okubangela ukungalungi njengokungahambi kahle kwendawo noma ukungabikhona kwamaphrofayili akhishiwe. Imigqa emikhulu ye-extrusion idonsa kanzima ngeyunifomui-polymer melt viscosity isilinganisongaphesheya kokugeleza, ukugcina ukuthobela ekulawuleni inqubo. Ekubumbeni umjovo onesivinini esikhulu, ukulungisa okwenziwa ngesandla kuyehluleka ukuhambisana nezikhathi zomjikelezo osheshayo, okubeka engcupheni i-warpage noma ukugcwaliswa okungaphelele. Lezi zinselele zigcizelela isidingo sokuthuthukai-viscometer ye-polymeramasistimu, njengei-viscometer ye-polymer ezenzakalelayo, ukuhlinzeka ngedatha yesikhathi sangempela futhi unqobe imikhawulo yezindlela zendabuko.

Kungani Melt Viscosity Monitoring Matters

Isilinganiso sokuncibilika kwe-viscosity sibalulekile kunqubo ye-polymer extrusion kanye nokubumba komjovo ngezizathu ezimbalwa. Ku-extrusion, i-viscosity encibilikayo engaguquguquki iqinisekisa ukugcwala kokufa okufanayo futhi ivimbele amaphutha afana nokungahambi kahle kwendawo noma ukuvuvukala kokufa. Ekubunjweni komjovo, kuthinta ukugcwaliswa kwesikhunta, ikhwalithi yengxenye, nesikhathi somjikelezo, lapho ukuhlukahluka kungaholela ekugcwalisweni kwe-warpage noma okungaphelele. Ukuqapha kwesikhathi sangempela kuvumela ama-opharetha ukuthi alungise izinga lokushisa, ingcindezi, noma ukwakheka kwezinto endizeni, okwandisa ukusetshenziswa kwamandla nokunciphisa imfucuza—izinto ezikhathazayo ezibalulekile njengoba imithetho yekhabhoni iqina ngo-2025.

Ubunkimbinkimbi besilinganiso se-viscosity ye-polymer melt buvela kumvelo okungeyona eye-Newtonian yokuncibilika kwe-polymer, lapho i-viscosity ihluka ngokwezinga lokugunda kanye nomlando wokushisa. Amasistimu we-inline polymer-melt viscometer systems abhekana nalokhu ngokunikeza idatha eqhubekayo, evumela ukulawulwa kwenqubo ukuthi izindlela ezingaxhunyiwe ku-inthanethi azikwazi ukufana.

Ubungcweti be-Lonnmeter Ekuqapheni i-Viscosity Monitoring

Ngesipiliyoni esingaphezu kweminyaka eyishumi,I-Lonnmeter, ohamba phambiliumphakeli we-polymer viscometer, isizimise njengephayona eukuqapha i-viscosity. Ubuchwepheshe babo buhlanganisa imigqa yokucindezela okuphezulu, izinga lokushisa eliphezulu kanye nezindawo zokubumba umjovo, ukubhekana nezidingo zama-polymer ahlukahlukene njenge-polyethylene, i-polypropylene, ne-PET.

Izixazululo Zomkhiqizo

I-Lonnmeter inikeza umkhawuloi-viscometer ye-polymer encibilikaizixazululo ezenzelwencibilikisa ukuqapha kwe-viscosity. II-Viscometer engaphakathiyakhelwe ukufakwa perpendicular noma parallel emishinini extrusion, ukulinganisancibilikisa i-viscositykufika ku-100,000 cP·s namazinga okushisa afika ku-300°C, akuthintwa ukuhlukahluka kokugeleza.

Ukwenza ngendlela oyifisayo kuwuphawu lweminikelo ye-Lonnmeter, enezinketho zokuxhunywa okuntambo noma okuphekiwe kanye nokuphuma kwedatha nge-4-20mA noma i-RS485, ehlanganisa ngaphandle komthungo nezinhlelo ezizenzakalelayo. Ku-extrusion, ukusethwa kwe-perpendicular kuqinisekisa ukuphazanyiswa okuncane kokugeleza.

Izinzuzo ze-Lonnmeter's Melt Viscosity Solutions

Ukuqinisekisa ikhwalithi:Isikhathi sangempelai-polymer melt viscosity isilinganisoiqinisekisa ama-extrudates angenasici kanye nezingxenye ezibunjiwe.

Ukusebenza Kwezindleko:Ukwehliswa kwemfucuza nokugcinwa kwezindleko zokusebenza kwehlisa.

Ukonga Amandla:Ukulungiswa okunembile kuthuthukisa ukusetshenziswa kwamandla.

Ukuvumelana nezimo:Ukuhambisana nama-polymers ahlukahlukene kusekela izidingo ezahlukahlukene zokukhiqiza.

Ukuphepha Okuthuthukisiwe:Ukutholwa kusenesikhathi kwe-viscosity anomalies kuvimbela ubunzima bemishini.

Imibuzo Evame Ukubuzwa

Kungani i-viscosity encibilikayo ibaluleke kakhulu kunokushisa noma ukucindezela?

I-Melt viscosity ithinta ngqo ukugeleza kokuncibilika, ukugcwaliswa kokufa, nokuvumelana komkhiqizo, okuvame ukudlula ithonya lokushisa noma ingcindezi. Isilinganiso esifanele se-viscosity se-polymer melt sivimbela amaphutha afana ne-warpage noma ukuvuvukala okufayo, okwenza kube semqoka ekulawuleni inqubo.

I-Lonnmeter iqinisekisa kanjani ukuhlanganiswa kwedatha?

I-othomathikhi ye-polymer viscometer ihlanganisa nge-4-20mA noma i-RS485 protocol, enikeza idatha yesikhathi sangempela ukulawula izinhlelo. Isazi-mlando saso esisebhodini, esifinyeleleka ngesofthiwe, sinikeza imininingwane yomlando, edlula imikhawulo ye-viscometer polymer evamile.

Yiziphi izici ezithonya ukuncibilika kwe-viscosity yama-polymers?

I-viscosity encibilikayo yama-polymers ithonywa isisindo samangqamuzana, izinga lokushisa, izinga lokugunda, kanye nokuba khona kwezithasiselo noma izigcwalisi. Isisindo samangqamuzana aphezulu kanye namazinga okushisa aphansi ngokuvamile akhulisa i-viscosity, okuthinta inqubo ye-polymer extrusion.

I-Melt viscosity monitoring iyisisekelo senqubo ye-polymer extrusion kanye nokubunjwa komjovo, okuqinisekisa ikhwalithi nokusebenza kahle. Ngobuchwepheshe obufakazelwe be-Lonnmeter kanye ne-viscometer ethuthukisiwe yama-polymers, abakhiqizi banganqoba izinselele ekulawuleni inqubo futhi bathuthukise ukukhiqiza. Cela ikhotheshini namuhla kulo mhlinzeki we-viscometer othembekile we-polymer!

Isikhathi sokuthumela: Jul-31-2025