I-Pulp Concentration Measurement

Ukugxila kwe-pulp esifubeni somshini kufinyelela ku-2.5-3.5% ngokujwayelekile. Amanzi ayadingeka ukuze kuhlanjululwe i-pulp ekugxiliseni okuphansi ukuze uthole imicu ehlakazeke kahle kanye nokususwa kokungcola.

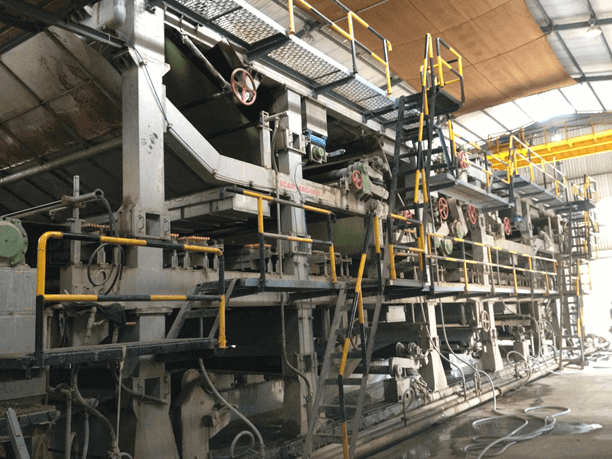

Ngobaimishini fourdrinier, ukugxiliswa kwe-pulp engena ku-mesh kungu-0.3-1.0% ngokujwayelekile ngokuya nezici ze-pulp, izakhiwo zemishini, kanye nekhwalithi yephepha. Kulesi sigaba, izinga lokuhlanjululwa lihambisana nokugxiliswa kwe-pulp edingekayo ku-mesh, okusho ukuthi ukugxilisa okufanayo kusetshenziselwa ukuhlanzwa, ukuhlungwa, kanye nokwakhiwa kwe-mesh.

Ukugxila kwe-pulp kuma-mesh kuphansi kuye ku-0.1–0.3% kuphela emishinini yamasilinda. Izinga lokugeleza ngokuhlanzwa nokuhlunga liphezulu kunezimfuneko ezine-pulp yokugxila ephansi. Ngaphezu kwalokho, amathuluzi amaningi okuhlanza nawokuhlunga ayadingeka ukuze kucutshungulwe i-pulp engagxili kakhulu, edinga imali eyengeziwe, indawo enkulu, amapayipi ayinkimbinkimbi, kanye nokusetshenziswa kwamandla okuphezulu.

Imishini yama-cylinder ivame ukusebenzisa ainqubo yokuhlanjululwa kwezigaba ezimbili,lapho ukuhlushwa kwehliselwa ku-0.5 ~ 0.6% okokuqala ekuhlanzeni kokuqala nokuhlunga; bese kwehliswa ukuze kuqondiswe ekugxiliseni phambili ngaphambi kokungena ku-mesh ebhokisini lokuzinzisa.

Ukuhlanjululwa kwe-pulp kusebenzisa amanzi amhlophe ngemeshi ngokujwayelekile ukongiwa kwamanzi nokutholwa kwemicu emihle, izigcwalisi, namakhemikhali emanzini amhlophe. Ukubuyiswa kwamanzi amhlophe kuyinzuzo yokongiwa kwamandla emishini edinga ukushisisa i-pulp.

Izici Eziyinhloko Ezithinta Ukugxiliswa Kwe-Pulp Ehlanganisiwe

Izinguquko Ekugxilweni Kwe-Pulp Ukungena Ebhokisini Elilawulayo

Ukushintshashintsha kokuvumelana okuvela ekushayweni noma ekushintsheni kwesistimu ephukile kungabangela ukuhluka kokugxila kwe-pulp. Ukungahambi kahle kwegazi ezifubeni zemishini kungaholela ekugxilweni kwe-pulp okungahambisani ezindaweni ezahlukene, okubangela ukungazinzi okuqhubekayo.

Ukugeleza Okungemuva Kokwalas phakathiUkuhlanzwa kanyeukuhlunga

Ukwenqatshwa kokuhlanzwa nokuhlunga kuvame ukubuyiselwa ohlelweni ngamanzi okuhlanza. Ukwehluka kwevolumu nokugxiliswa kwalokhu kunqatshwa kuncike ekusebenzeni kwempahla yokuhlanza nokuhlunga kanye namazinga oketshezi kuma-inlets wepompo.

Lezi zinguquko zidala umthelela ekugxilweni kwamanzi amhlophe asetshenziselwa ukuhlanjululwa futhi, ngokulandelayo, ukugxila kokugcina kwe-pulp. Izinkinga ezifanayo zingenzeka ezinhlelweni zokubuyisela amathangi omshini wesilinda.

Ukwehluka kokugxiliswa kwe-pulp ehlanjululwe kungathinta kokubili ukusebenza komshini wephepha kanye nekhwalithi yokugcina yephepha. Ngakho-ke, kubalulekile ukuqapha ngokucophelela ukugxila kwe-pulp ngeukungaguquguquki imitha pulpekhiqizwa nguI-Lonnmeterngesikhathi sokukhiqiza futhi ulungise ukungena ebhokisini elilawulayo ukuze kugcinwe ukugxila okuzinzile. Imishini yesimanje yephepha ivamise ukusebenzisa izinsimbi ezizenzakalelayo ukuze:

- Lungisa ngokuzenzakalelayo i-ukugxila kwe-pulpukungena ebhokisini elilawulayo.

- Lungisa ukungena okusekelwe ekushintsheni kwesisindo sesisekelo sephepha kanyeheadbox pulp concentration.

Lokhu kuqinisekisa ukugxila kwe-pulp ezinzile.

Izinzuzo Zokulungiswa Kwendawo Ye-Pulp Ehlanganisiwe

Ukulawulwa kokugxilwa kwezinzuzo ze-pulp ehlanjululwe kukho kokubili ukusebenza kahle komshini wephepha nokugcinwa kwekhwalithi yephepha.

Okwemishini Yesilinda

Uma i-pulp inezinga eliphansi lokushaya futhi i-dewaters ngokushesha, amazinga amanzi angaphakathi nangaphandle engxenyeni ye-mesh ayancishiswa, okwenza buthaka ukunamathiselwa kwesendlalelo sephepha ku-mesh. Lokhu kwandisa umphumela wokuhlushwa, kunciphisa ukuchichima, futhi kwandisa umehluko wejubane phakathi kwe-pulp ne-mesh, okuholela ekwakhekeni kwephepha elingalingani.

Ukuze kubhekwane nalokhu, ukusetshenziswa kwamanzi amhlophe kuyanyuswa ukuze kwehlise ukugxila kwe-pulp, kukhuphule izinga lokugeleza kumeshi. Lokhu kuphakamisa umehluko wezinga lamanzi, kwandisa ukuchichima, kunciphisa imiphumela yokugxilisa ingqondo, futhi kunciphise ukuhluka kwesivinini, ngaleyo ndlela kuthuthukisa ukufana kweshidi.

Okwemishini yeFourdrinier

Amadigri aphezulu okushaya enza ukugeleza kube nzima, kunwebe umugqa wamanzi, kwandise umswakama eshidini elimanzi, futhi kuholele embossing noma ukuchotshozwa ngesikhathi sokucindezela. Ukuqina kwephepha kuwo wonke umshini kunciphisa, futhi ukushwabana ngesikhathi somiswa kuyanda, kubangele amaphutha njengokugoqa kanye nemibimbi.

Ukuze unqobe lezi zinselele, ukugxilwa kwe-pulp ehlanganisiwe kunganyuswa ngokunciphisa ukusetshenziswa kwamanzi amhlophe, kunciphise izinkinga zokugeleza kwamanzi.

Ngakolunye uhlangothi, uma izinga lokushaya liphansi, imicu ivame ukuntanta, futhi ukugeleza kwamanzi kwenzeka ngokushesha kakhulu kumeshi, kuthinte ukufana kwephepha. Kulokhu, ukwandisa ukusetshenziswa kwamanzi amhlophe ukwehlisa ukugxila kwe-pulp ehlanjululwe kunganciphisa ukugeleza futhi kuthuthukise ukufana.

Isiphetho

I-Dilution kuwumsebenzi obalulekile ekwenzeni iphepha. Ekukhiqizeni, kubalulekile uku:

- Gada eduze futhi ulawule ngokuqinile izinguquko ku-dilutedukugxila kwe-pulpukuqinisekisa ukusebenza okuzinzile.

- Naka izinguquko zekhwalithi yomkhiqizo nezimo zokusebenzafuthi, lapho kudingekile, lungisa ukugxila kwe-pulp njengethuluzi lokunqoba ubunzima obufana nalezi ezishiwo ngenhla.

Ngokuphatha ngempumelelo ukuhlanjululwa kwe-pulp, ukukhiqizwa okuzinzile, iphepha lekhwalithi ephezulu, nokusebenza kahle kungafinyelelwa.

Isikhathi sokuthumela: Jan-24-2025