Ikhwalithi engaguquki ibalulekile ekukhiqizweni kwezidakamizwa ekukhiqizeni imithi. Ukuqapha nokulawula inqubo ye-crystallization yezimboni kudlala indima ebalulekile ekufezeni lezi zinhloso, ikakhulukazi ekugcineni ubumsulwa, ifomu lekristalu, kanye nokusatshalaliswa kosayizi wezinhlayiyana zezithako ezisebenzayo zemithi (ama-API). Ukuqapha i-Crystallization, ikakhulukazi embonini yezemithi, kwenza abakhiqizi bakwazi ukuthuthukisa izinqubo, behlise izindleko, futhi bahlangabezane nezindinganiso eziqinile zokulawula. Ngobuchwepheshe obuthuthukisiwe obufana nokuqapha kwe-crystallization ye-ultrasonic, ukutholwa kwedatha yesikhathi sangempela kuguqule indlela amafekthri ezenza imithi aphatha ngayo izinqubo eziyinkimbinkimbi ze-crystallization.

Ukubaluleka kweCrystallization Monitoring ku-Pharmaceuticals

I-Crystallization iyisinyathelo esibalulekile ekwenziweni kwemithi, esetshenziselwa ukuhlanzwa nokwakhiwa kwama-API. Inqubo inquma izici ezibonakalayo namakhemikhali zomkhiqizo wokugcina womuthi, okuhlanganisa ukuncibilika, i-bioavailability, kanye nokuzinza. Usayizi wekristalu ongaguquki, umumo, noma i-polymorphism kungaholela ekuhlukeni kokusebenza kahle kwezidakamizwa, okudala izingozi ekuphepheni kwesiguli nokuthobela imithetho. Ukuqapha kwe-crystallization yezemithi kuqinisekisa ukuthi lezi zakhiwo zilawulwa ngesikhathi sangempela, kunciphisa ukuhlukahluka kwe-batch-to-batch nokuqinisekisa ukuphuma kwekhwalithi ephezulu.

Izinselelo Ezinqubweni Zomdabu Ze-Crystallization

Izindlela zendabuko zokucwebezelisa zivame ukuncika ekuthathweni kwesampula okungaxhunyiwe ku-inthanethi nokuhlaziywa kwaselabhorethri, okwethula ukubambezeleka futhi kwandise ubungozi bamaphutha. Lezi zindlela ziyazabalaza ukuze zithwebule izinguquko eziguquguqukayo enqubweni efana nokuguquguquka kwe-supersaturation. Ukwengeza, ukungenelela okwenziwa ngesandla kungaholela ekungasebenzini kahle, ukusetshenziswa kwamandla okuphakeme, kanye nokwanda kokumoshakala kwezinto ezibonakalayo. Ngokwamukela amasu okulawula i-crystallization asekelwa ukuqapha kwesikhathi sangempela, izimboni zemithi zinganqoba lezi zinselele, zithole ukusebenza kahle okukhulu nokonga izindleko.

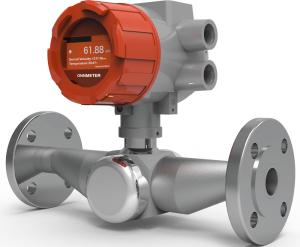

I-Lonnmeter Inline Concentration Measurement for Crystallization Process Optimization

Ukuhlanganiswa ne-PLC noma i-DCS Systems Yokulawula Isikhathi Sangempela

Ukuhlanganiswa okungenazihibe ohlelweni lwe-PLC noma lwe-DCS kuguqule ukuqapha nokulawula inqubo ye-crystallization yezimboni, okuvumela ukuqapha kwesikhathi sangempela phezu kwemingcele yenqubo ebalulekile njengokugxilisa ingqondo namazinga okushisa. Lobu buchwepheshe buvumela abakhiqizi ukuthi baqaphe usayizi wekristalu, umumo, kanye ne-polymorphism ngaphandle kokuphazamisa ukukhiqizwa, ukuqinisekisa ikhwalithi engaguquki. Ukwengeza, uhlelo lokulawula oluhlakaniphile luvumela ukulungiswa okunembile kumazinga okushisa, ukwakheka kwe-solvent, namazinga okuxuba, okwenza yonke inqubo iphumelele.

Izinzuzo ze-Ultrasonic Crystallization Monitoring

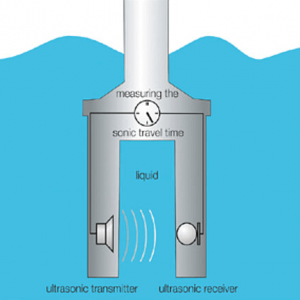

I-Ultrasonic crystallization monitoring igqama ngenxa yamakhono ayo angahlaseli, anembe kakhulu. Izinzwa zokugxilisa ingqondo ze-Ultrasonic zikala isivinini samaza omsindo nge-liquid medium, zihlobanisa lezi zilinganiso nezici zokugxilisa ingqondo nekristalu. Lobu buchwepheshe buhamba phambili ezindaweni eziguqukayo, bunikeza idatha yesikhathi sangempela enezikhathi zokuphendula eziphansi njengesekhondi elilodwa. Ngokungafani nezindlela zendabuko, ukuqapha kwe-ultrasonic akuthintwa yizici ezifana nombala owuketshezi noma i-conductivity, okwenza kube ilungele izinqubo eziyinkimbinkimbi zemithi.

Amasu e-Ultrasonic aphinde athuthukise i-nucleation nokukhula kwekristalu ngokufaka i-cavitation, okudala i-supersaturation efanayo futhi kunciphise isikhathi sokungeniswa. Lokhu kuholela kusayizi wekristalu ongaguquguquki kanye ne-morphology, okubaluleke kakhulu ekusetshenzisweni kwemithi efana ne-lactose crystallization noma ukukhiqizwa kwe-API.

Izinzuzo zokuqapha i-crystallization ye-ultrasonic zifaka:

- Idatha Yesikhathi Sangempela: Impendulo esheshayo ngezimo zenqubo, evumela ukulungiswa okusheshayo.

- Ukunemba Okuphezulu: Izilinganiso ezinembile zokugxilisa ingqondo nezakhiwo zekristalu, ezinamaleveli anemba afinyelela ku-±0.05 m/s ngesivinini se-ultrasonic.

- Umsebenzi Ongahlaseli: Asikho isidingo sokuthatha amasampula, ukunciphisa ubungozi bokungcola kanye nesikhathi sokuphumula.

- I-Versatility: Ifanele izinqubo ezehlukene zemithi, kusukela ku-R&D esezingeni elincane ukuya ekukhiqizweni kwezinga elikhulu.

Ngokuhlanganisaamamitha okuhlushwa asemgqeniezinhlelweni ze-crystallization, abakhiqizi bangafinyelela ukulawulwa kwe-crystallization okwandisa isivuno, kunciphisa ukusetshenziswa kwamandla, nokuqinisekisa ukuhambisana nokulawula.

Izicelo Ezisebenzayo Ekwenziweni Kwemithi

Ukuthuthukisa i-Lactose crystallization

Ekukhiqizweni kwemithi, i-lactose ivamise ukusetshenziswa njengesamukeli ekwenziweni kwethebhulethi. Ukulawula inqubo yayo ye-crystallization kubalulekile ukuze kuqinisekiswe usayizi wezinhlayiyana ezingaguquki kanye nokuncibilika. Izinhlelo zokuqapha icrystallization yezemithi, ikakhulukazi lezo ezisebenzisa ubuchwepheshe be-ultrasonic, zisetshenziswe ngempumelelo ukuqapha i-lactose crystallization ngesikhathi sangempela.

Ukuqinisekisa Ukulawulwa Kwe-Polymorphism

I-Polymorphism, ikhono lenhlanganisela ukuthi libe khona kumafomu ekristalu amaningi, iyisici esibalulekile ekukhiqizeni imithi. Ama-polymorphs ahlukene angathinta izinga lokuqedwa komuthi kanye ne-bioavailability. Ukuqapha kwe-Crystallization ngemitha yokuhlushwa ye-Lonnmeter ultrasonic kusiza ukukhomba nokulawula amafomu e-polymorphic ngesikhathi sangempela. Ngokugcina izimo ezifanele, iumqaphi wenqubo esemgqeniiqinisekisa ukuthi i-polymorph efiselekayo ikhiqizwa ngokuqhubekayo, inciphisa ingozi yokwehluleka kweqoqo kanye nokusebenza kabusha okubizayo.

Imibuzo Ejwayelekile Mayelana Nokuqapha I-Crystallization (FAQs)

Ithini Iqhaza Lokuqapha I-Crystallization Kwezemithi?

Ukuqapha kwe-Crystallization kwezemithi kuqinisekisa ukukhiqizwa okungaguquki kwama-API anezakhiwo ezifiselekayo, njengokuhlanzeka, usayizi wekristalu, kanye ne-polymorphism. Ngokuhlinzeka ngedatha yesikhathi sangempela, amathuluzi okuqapha njengezinzwa ze-ultrasonic kanye nezinhlelo ze-PAT zisiza abakhiqizi balondoloze izimo zenqubo ezifanele, banciphise ukuhlukahluka, futhi baqinisekise ukuthobela izindinganiso zokulawula.

I-Ultrasonic Crystallization Monitoring Ithuthukisa Kanjani Ukusebenza Ngempumelelo?

Ukuqapha kwe-crystallization ye-Ultrasonic kuthuthukisa ukusebenza kahle ngokunikeza izilinganiso ezingavamisi, zesikhathi sangempela zokugxila kanye nezakhiwo zekristalu. Yehlisa isikhathi sokungeniswa, inciphise ukusetshenziswa kwamandla, futhi ivimbele ukwehluleka kwenqwaba ngokunika amandla ukulawula okunembile phezu kwe-nucleation nokukhula kwekristalu.

Yiziphi Izinzuzo Zezindleko Zokulawula I-Crystallization Yesikhathi Sangempela?

Ukulawulwa kwenqubo ye-crystallization yesikhathi sangempela kunciphisa ukumosheka kwezinto, ukusetshenziswa kwamandla, nesikhathi sokuphumula, okuholela ekongeni kwezindleko ezibalulekile.

Ukuqapha nokulawula inqubo ye-crystallization yezimboni kuwukushintsha umdlalo wokwenziwa kwemithi, okunikeza ukunemba okungenakuqhathaniswa nokusebenza kahle. Ukulawula i-Crystallization ngedatha yesikhathi sangempela akugcini nje ngokuthuthukisa ikhwalithi yomkhiqizo kodwa futhi kuqondisa ukusebenza, okwenza kube ukutshalwa kwezimali okubalulekile kunoma iyiphi imboni yezokwelapha.

Xhumana nethimba lethu namuhla ukuze uhlole izixazululo ezithuthukisiwe zokuqapha i-crystallization ezihambisana nezidingo zakho. Vakashela iwebhusayithi yethu ukuze uthole ukubonisana kwamahhala futhi uthole ukuthi ukuqapha ngesikhathi sangempela kungakhuphula kanjani ukukhiqiza kwakho kahle kanye nekhwalithi.

Isikhathi sokuthumela: Jul-03-2025