Ingabe uhlushwa ngamanzi amaningi ku-underflow kanye nezinto eziqinile ekuchichimeni? Ingabe uhlose ukuthuthukisa ukusebenza kokuqina ngokususa ukukalwa kwabantu okuphindaphindiwe namaphutha omuntu? Abasebenzisi abaningi bokugcina babhekana nezinkinga ezifanayo embonini yokucubungula izimbiwa ukuze bonge amanzi futhi baqoqe izinto ezibalulekile ukuze zicutshungulwe. Imitha yesikhathi sangempela sokuminyana isebenza kahle ekufinyeleleni le migomo.

I-athikili elandelayo igxile ekuchazeni izinjongo nezinzuzo zokulawula ukuminyana ezindaweni ezihlukene zamathangi okuqina. Ake siqale ngesingeniso esifingqiwe senqubo yokujiya, silandelwe yizizathu ezinhlanu zokukala ukuminyana enqubweni yokuhlukanisa.

Uyini Umsebenzi Wokuqina?

Inqubo yokuqina ihlanganisa ukuhlukaniswa kwengxube yoketshezi oluqinile ukuya ekugelezeni okuncane okuminyene kanye nokuchichima okucacile ngokujwayelekile. Owokuqala uqukethe izinhlayiya eziqinile futhi lokhu okulandelayo akufaki ukungcola ngangokunokwenzeka. Inqubo yokuhlukanisa ingumphumela wamandla adonsela phansi. Zonke izinhlayiya ezinobukhulu obuhlukahlukene kanye nokuminyana zakha izingqimba ezihlukene ngethangi.

Izinqubo zokujiya zenzeka ethangini le-sedimentation ekucutshungulweni kwezimbiwa ukuze kuhlukaniswe okugxilile kanye nemisila.

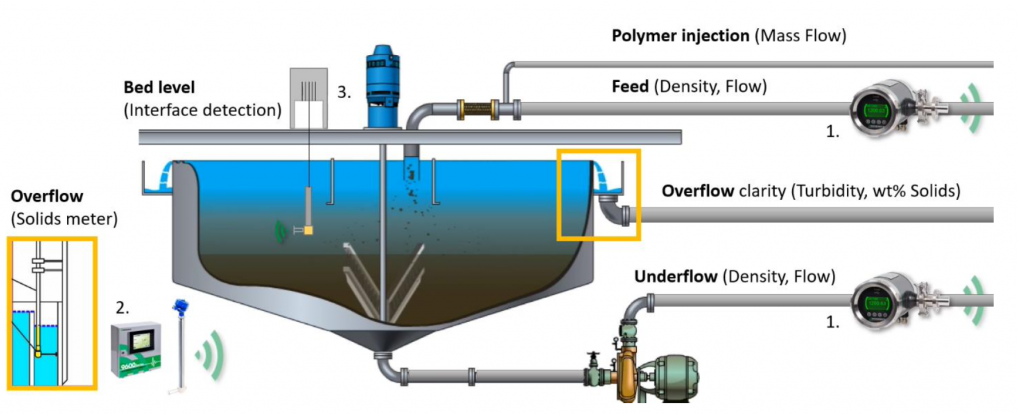

Amaphuzu Okulinganisa Adingekayo Ekuqinisweni

Amamitha we-liquid density ku-inthanethiziyadingeka ukuze kuthuthukiswe ukusebenza kwama-thickeners. Isibonelo, izindawo zokufaka zihlanganisa okuphakelayo, ukuchichima, ukuchichima kanye nengaphakathi lethangi eliwugqinsi. Ezimweni ezingenhla, lezi zinzwa zingathathwa njengeimitha ye-slurry densitynomaimitha ye-sludge density. Zibuye zibe usizo ekuthuthukiseni ukulawula okuzenzakalelayo kokushayela, amaphampu kanye nokulinganisa okusebenzayo kwama-flocculants.

Izizathu Zokukala Ukuminyana

Izizathu zokulinganisa ukuminyana zingahluka ngayinye ngayinye. Lezi zimo ezinhlanu ezilandelayo zigqamisa ukubaluleka kokuqapha ukuminyana ukuze kuthuthukiswe izimboni.

No. 1 Ukubuyisela Amanzi

Amanzi athathwa njengomunye wempahla ebaluleke kakhulu embonini yezimayini nezimbiwa phansi. Ngakho-ke, ukubuyiswa kwamanzi noma ukusetshenziswa kabusha kwamanzi konga izindleko zokujiya kakhulu. Ukukhula okuncane okungu-1-2% kokuminyana okungagelezi kahle kusho inani elikhulu lamanzi adingekayo ekufakweni kokusebenza. Ukwenyuka kokuminyana kusebenza ngempumelelo ekuqinisekiseni ukuqina emadamini asalayo, angase awe uma kwenzeka kuba noketshezi oluningi olumpontshelwa emadamini.

No. 2 Ukubuyiselwa Kwamaminerali

Ku-concentrate thickeners, okuphakelayo kuvame ukuvela kumjikelezo we-flotation. I-Flotation ihlanganisa ukuhlukanisa izinhlayiya ngokusebenzisa amandla adonsela phansi. Ngamanye amazwi, lawo anamabhamuza omoya anamathiselwe akhuphukela phezulu futhi asuswe, kanti amanye asala esigabeni soketshezi. Uma le nqubo yenzeka ku-thiener yomkhiqizo, igwebu lingathwala izinto eziqinile zibe zichichima.

Lezi zinto eziqinile zibalulekile futhi, uma zingatholakali, zinganciphisa izinga lokutholwa kwensimbi egxilile. Ukwengeza, izinto eziqinile ezichichimayo zingaholela ezindlekweni eziphezulu ze-reagent, ukulimala kwamaphampu namavalvu, kanye nezindleko zokulungisa ezikhuphukayo, njengokuhlanza amathangi amanzi lapho okuqinile kunqwabelana lapho.

Cishe u-90% wezinto eziqinile ezilahlekile ekuchichimeni ekugcineni zitholakala ezigabeni zakamuva zenqubo (isb., emathangini nasemadamini). Kodwa-ke, u-10% osele, omele inani elibalulekile lezomnotho, ulahleka unomphela. Ngakho-ke ukwehlisa ukulahleka kwezinto eziqinile zibe ukuchichima kufanele kube yinto ehamba phambili. Ukutshala imali kubuchwepheshe bokulawula inqubo kungathuthukisa amanani okuthola kabusha futhi kulethe imbuyiselo esheshayo ekutshalweni kwezimali.

Ukusetshenziswa kweLonnmeterdensity metresfuthiama-flow metresku-underflow kunika amandla ukuqapha okungcono kokusebenza kwe-thickener. Ukutholwa kwesikhathi sangempela kokuqinile ekuchichimeni nakho kungenzeka ngamamitha wokuminyana noma okuqinile. Amasiginali we-4-20mA wezinsimbi angahlanganiswa ohlelweni lokulawula ukuze kuthuthukiswe inqubo eqondile.

3 Ukusetshenziswa Kwe-Flocculant Okuphumelelayo

Ama-Flocculants asebenza ekuthuthukiseni ukusebenza kahle kwe-sedimentation, okungukuthi amakhemikhali enza ukuthi izinhlayiya eziwuketshezi zihlangane ndawonye. Umthamo we-flocculants ubheka ukulawulwa kwezindleko phezu kwe-reagent nokusebenza kahle kokusebenza. Imitha yokuminyana ivumela ukulawula ukuminyana okunembile nokuthembekile kokuphakelayo kwe-thickener. Umgomo uwukuthola amaphesenti aphakeme kakhulu okuqinile okuqinile ngesisindo ku-slurry feed kuyilapho usavumela izinhlayiyana zamahhala ezihlalayo. Uma ukuminyana kwe-feed slurry kudlula okuhlosiwe, inqubo yotshwala eyengeziwe kufanele yengezwe, futhi kungase kudingeke amandla engeziwe okuhlanganisa ukuze kuqinisekwe ukuthi ukudla kuxutshwa kahle.

Isilinganiso sesikhathi sangempela sokuminyana kwe-slurry yesiphakeli sisebenzisa imitha yokuminyana emgqeni sibalulekile ekulawuleni inqubo. Lokhu kuqinisekisa ukusetshenziswa okusebenzayo kwe-flocculant futhi kuthuthukisa inqubo yokuhlanganisa, kugcina i-thickener isebenza ngaphakathi kwebanga layo eliqondiwe.

4 Ukutholwa Ngokushesha Kwezinkinga Ze-Flocculation

Ama-opharetha alwela ukugcina izimo ezinyakazayo kuma-thieners, afinyelele ukuchichima okucacisiwe okuqinile okuncane kanye nokuchichima okungaphansi koketshezi oluncane. Kodwa-ke, izimo zenqubo zingashintsha ngokuhamba kwesikhathi, okungase kuholele ekuzinziseni kahle, ukunciphisa ukuminyana kokugeleza okuncane, kanye nokuqinile okuphezulu ekuchichimeni. Lezi zinkinga zingasukela ezinkingeni ze-flocculation, umoya noma igwebu ethangini, noma ukugxila kokuqinile okuphakeme kakhulu kokuphakelayo.

Amathuluzi nokusebenza okuzenzakalelayo kungasiza opharetha bagcine ukulawula ngokuthola izinkinga ezinjalo ngesikhathi sangempela. Ngaphandle kwezilinganiso ezingaphakathi komugqa, izinsimbi ezisekelwe ethangini njengama-ultrasonic bed level probes zinganikeza imininingwane ebalulekile. Lezi ziphenyi “zokutshuza” zihamba phansi naphezulu ethangini, zichaza amazinga odaka, izindawo zokuhlala, nokucaca okuchichimayo. Izilinganiso zezinga lombhede ziwusizo ikakhulukazi kumasu okulawula ukugeleza, okuqinisekisa ukusebenza okungaguquki.

I-Slurry Density Meter (SDM)

I-Slurry Density Meter (SDM) iyindlela evumelana ne-eco-friendly kumamitha avamile we-nuclear density. Ithole ukuthandwa ngokushesha, ngamakhulu okufakwa emhlabeni jikelele. I-SDM ihlinzeka ngezilinganiso ezinembile nezithembekile zokuminyana, okuyenza ibe yisixazululo esifanelekile sezitshalo zanamuhla zokucubungula amaminerali.

Ukuminyana kokulinganisa kudlala indima ebalulekile ekuthuthukiseni ukusebenza kahle kokuqina futhi kusebenza njengenkomba yokusebenza eyinhloko yokulawula inqubo. Ngokwamukela ubuchwepheshe bokulinganisa obuthuthukisiwe namasu okulawula inqubo, opharetha bangakwazi ukuthuthukisa ukusebenza okujiyile, bathuthukise amanani okuthola kabusha, futhi banciphise izindleko zokusebenza.

Isikhathi sokuthumela: Dec-30-2024