I-Titanium Dioxide (TiO2, i-titanium(IV) oxide) isebenza njengesihluthulelo sombala omhlophe kumapende nama-coatings, nanjengesivikelo se-UV kumakhilimu elanga. I-TiO2 ikhiqizwa kusetshenziswa enye yezindlela ezimbili eziyinhloko: inqubo ye-sulfate noma inqubo ye-chloride.

Ukumiswa kwe-TiO2 kufanele kuhlungwe futhi komiswe. Kulokhu ngemva kokwelashwa inqubo eqhubekayo yokuqapha nge-TiO2 ukumiswa kokuminyana iyadingeka ukuze kuqinisekiswe ikhwalithi yomkhiqizo ophezulu kanye nokusebenzisa ngokugcwele umthamo wezitshalo. Ukunemba kubaluleke kakhulu ekuqinisekiseni ikhwalithi engaguquki yeisixazululo se-titanium dioxide.

Kungani Ukuminyana Kubalulekile Ku-Titanium Dioxide Ngemva Kokwelashwa

Ukukhiqizwa kwe-TiO2 kuhilela izinqubo eziyinkimbinkimbi, ngokuvamile indlela ye-sulfate noma ye-chloride, elandelwa izigaba zangemuva kokwelashwa ezifana nokugcotshwa kwendawo, ukugaya, nokomisa. Phakathi nalezi zigaba, i-TiO2 ivame ukuphathwa njengokumiswa, lapho i-ukuminyana kwesisombululo se-titanium dioxideithinta ngokuqondile izici zomkhiqizo wokugcina, njengokucwebezela, ubumhlophe, nokuqina. Ukwehluka kokuminyana kungaholela ekusetshenzisweni kwe-coating okungahambisani noma ezinkingeni zokuhlunga, okuholela emikhiqizweni enesici kanye nezindleko ezikhulayo.

Aimitha ye-titanium dioxide densityinikeza idatha yesikhathi sangempela mayelana nokuminyana kokumiswa, okuvumela abakhiqizi ukuthi balungise amapharamitha enqubo ngokushesha. Ngokugcina ukulawula okunembe phezu kweisixazululo se-titanium dioxide, abakhiqizi bangaqinisekisa ukufana kusayizi wezinhlayiyana nokuphathwa kwendawo, okubalulekile ekuhlangabezaneni nezindinganiso zomkhakha. Isibonelo, ekukhiqizeni upende, ukuminyana okungaguquki kuqinisekisa ukuhlakazeka kwe-pigment okufanelekile, kukhuphula umbala kanye nekhwalithi yokumboza.

Izinselelo Ngaphandle Kokuqapha Ukuminyana Okusemgqeni

Ngaphandle kokuqapha okufanele kokuminyana, abakhiqizi babhekana nezinselele eziningana. Ukusampula okwenziwa mathupha, nakuba kuvamile, kudla isikhathi futhi kujwayele ukuba namaphutha, okuholela ekubambezelekeni ekuboneni ukuchezuka kokuminyana. Lokhu kungahambisani kungabangela izinkinga ezifana nezihlungi ezivalekile, ama-coatings angalingani, noma ukunciphisa impilo yeshalofu yomkhiqizo. Ngaphezu kwalokho, izindlela ezenziwa ngezandla azikwazi ukunikeza impendulo eqhubekayo edingekayo ukuze kulungiswe inqubo eguquguqukayo, okuholela ekungasebenzi kahle kanye nezindleko eziphezulu zokusebenza. Ukusebenzisa inzwa ye-titanium dioxide density ibhekana nalezi zinselele ngokunikeza ukuqapha okuzenzakalelayo, kwesikhathi sangempela, ukunciphisa amaphutha abantu, nokuthuthukisa ukukhiqizwa kokukhiqiza.

Izinhlobo ze-Lonnmeter Density Monitoring Solutions ze-TiO2

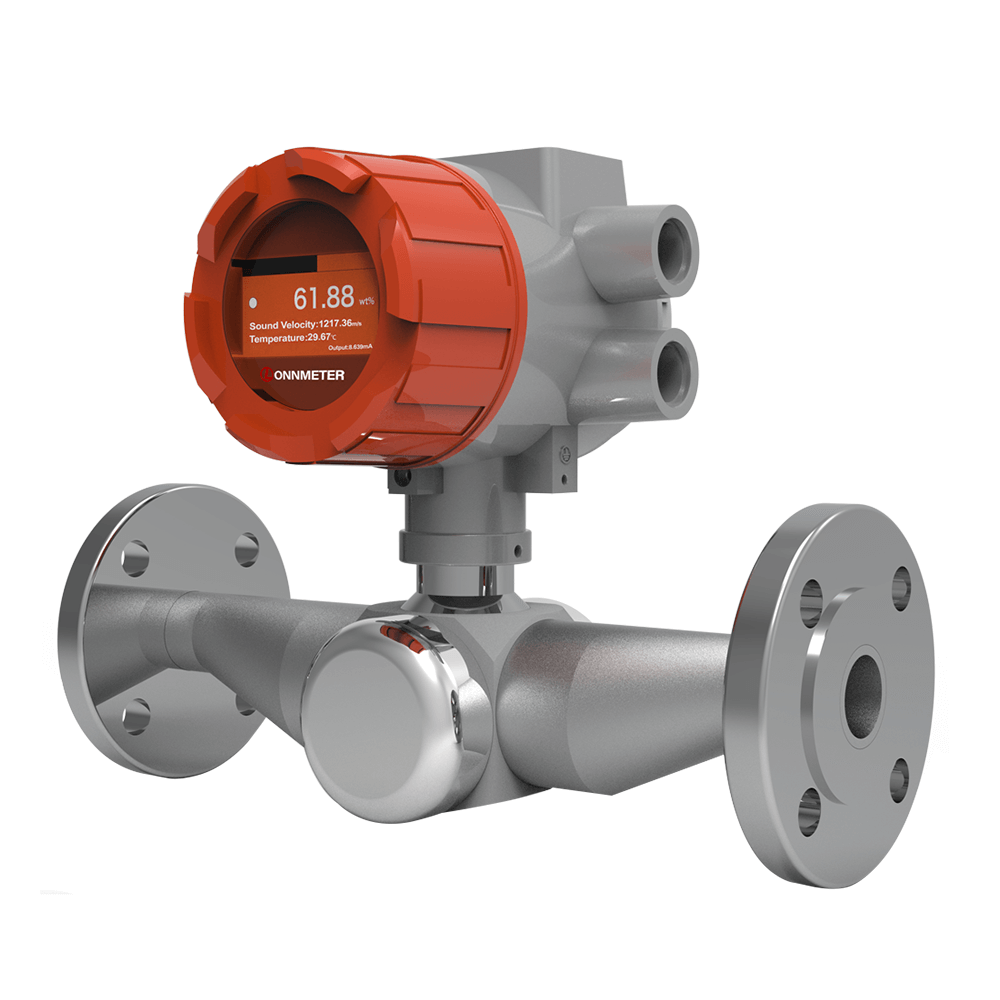

Amamitha we-tube density metres aphakathi kwamathuluzi asetshenziswa kakhulu okuqapha ukuminyana kwesixazululo se-titanium dioxide. Lawa madivayisi asebenza ngokulinganisa imvamisa yeshubhu elidlidlizayo elimise okuka-U eligcwele ukumiswa kwe-TiO2. Imvamisa ishintsha ngokuphambene nokuminyana kwesixazululo, inikeze izilinganiso ezinembile, zesikhathi sangempela.

Izinzwa ze-Titanium dioxide density ezisekelwe kubuchwepheshe be-ultrasonic zinikeza isisombululo esingahlaseli sokuqapha ukuminyana. Lezi zinzwa zikala isivinini samagagasi omsindo ngokumiswa kwe-TiO2, okuhambisana nokuminyana kwakho. Izinzwa ze-Ultrasonic zisebenza kahle kakhulu kuma-slurries aphezulu-concentration, njengoba akuthintwa ukufiphala noma umbala wesixazululo.

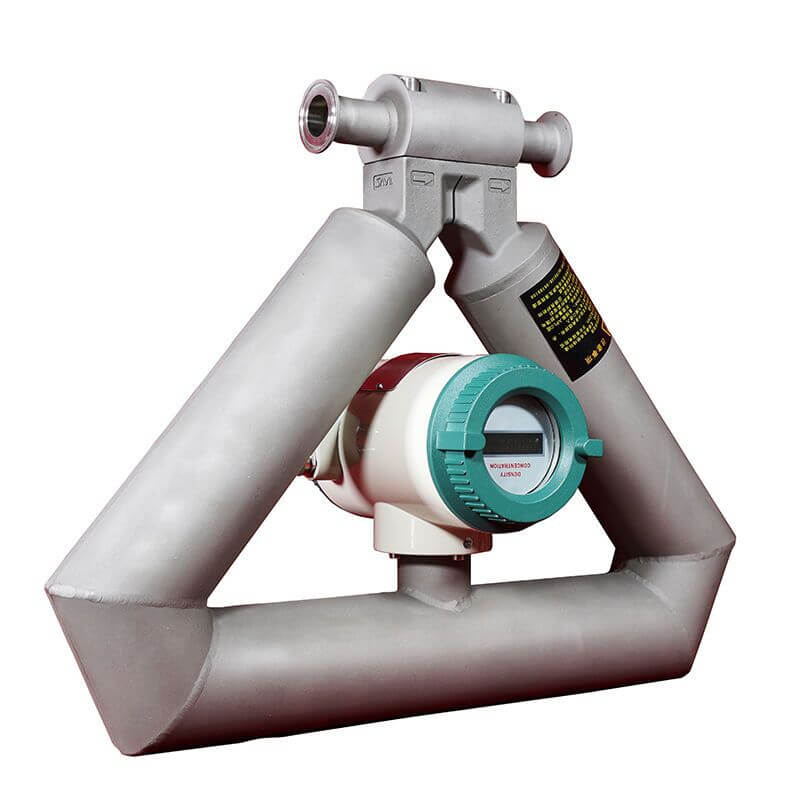

Amamitha we-Coriolis density ahlinzeka ngokusebenza okumbaxambili, ukulinganisa kokubili ukuminyana nokugeleza kwenqwaba, okuzuzisa abakhiqizi be-TiO2 abafuna ukulawulwa kwenqubo okuphelele. Lawa mamitha asebenzisa umphumela we-Coriolis, lapho ukudlidliza kweshubhu kuguqulwa ukugeleza nokuminyana kokumiswa. Ikhono labo lokuphatha ububanzi bamazinga okuminyana libenza basebenzise izinto ezihlukahlukene ezigabeni ezihlukahlukene zokukhiqiza i-TiO2, kusukela emathangini okugcina kuya ezinhlelweni zokuhlunga.

Izinzuzo Zokuqapha Ukuminyana Okusemgqeni Kwabakhiqizi be-TiO2

Ikhwalithi Yomkhiqizo Ethuthukisiwe

Ukusebenzisa i-titanium dioxide density monitor kuqinisekisa ukuminyana okungaguquki kuyo yonke inqubo yangemva kokwelashwa, okunomthelela ngqo kwikhwalithi yomkhiqizo. Isibonelo, ukugcina ukuminyana okuhle ngesikhathi sokumbozwa kwendawo kuvimbela izinkinga ezifana ne-particle agglomeration, engehlisa isithunzi ukusebenza kwe-pigment ekusetshenzisweni kokugcina. Ukulungiswa kwesikhathi sangempela okusekelwe kudatha yokuminyana kuqinisekisa ukuthi i-TiO2 ihlangabezana nezindinganiso eziqinile zekhwalithi, okuthuthukisa ukuncintisana kwayo ezimakethe.

Ukusebenza Kahle Kwezindleko Nokwehliswa Kwemfucuza

Ukuqapha ukuminyana okusemgqeni kunciphisa izindleko zokusebenza ngokunciphisa ukumosha nokuthuthukisa ukusetshenziswa kwezinsiza. Ngokuthola ukuchezuka kokuminyana khona manjalo, abakhiqizi bangalungisa ukugcwala kwesixazululo se-titanium dioxide ngaphambi kokuba kukhiqizwe amaqoqo anesici. Le ndlela yokwenza izinto inciphisa ukumosheka kwezinto kanye nokusetshenziswa kwamandla, okuholela ekongeni kwezindleko ezibalulekile.

Ukusebenza Okuthuthukisiwe Kokukhiqiza

Impendulo yesikhathi sangempela enikezwa imitha ye-titanium dioxide density ivumela ukulungiswa kwenqubo ngokushesha, ukunciphisa isikhathi sokuphumula nokwandisa ukuphuma. Isibonelo, ukufaka inzwa yokuminyana ngaphambi kwethangi lesitoreji noma iyunithi yokuhlunga kunika amandla opharetha ukuthi balungise kahle ukugxila kokumiswa ngemizuzwana. Leli khono libaluleke kakhulu ezindaweni zokukhiqiza ezinevolumu ephezulu, lapho ukubambezeleka okuncane kungaba nomthelela enzuzweni.

Ukuhambisana Namazinga Omkhakha

Abakhiqizi be-TiO2 kufanele bahambisane nezindinganiso eziqinile zokulawula. Ukuqapha ukuminyana okusemgqeni kuqinisekisa ukuthobelana ngokuhlinzeka ngedatha elandelekayo kumapharamitha wenqubo. Lokhu kungafihli kubalulekile ekucwaningeni nasekunikezweni kwezitifiketi, okuthuthukisa isithunzi somkhiqizi nokuthenjwa kwemakethe.

Amasu Okusebenzisa Okuqapha Ukuminyana Okusemgqeni

Ukukhetha Iphoyinti Lokufaka Elilungile

Ukukhetha indawo efanelekile yokufaka inzwa ye-titanium dioxide density kubalulekile ukuze kuqashwe ngempumelelo. Kunconywa izindawo ezimbili eziyinhloko:

Ngaphambi Kwethangi Lesitoreji: Ukufaka imitha yokuminyana ngaphambi kwethangi lokugcina kuqinisekisa ukuthi ukumiswa kwe-TiO2 okungena ethangini kuhlangabezana nezicaciso zokuminyana ezidingekayo. Lokhu kusetha kulungele ukugcina ukuvumelana phakathi nesigaba sokuqala sokuqoqwa, ukuvimbela izinkinga ezansi nomfula.

Esigabeni Sokuhlunga: Ukubeka imonitha yokuminyana esigabeni sokuhlunga kuvumela ukulawula okunembile phakathi nenqubo yokomisa. Lokhu kuqinisekisa ukuthi ukuminyana kokulengiswa kuhlala kuzinzile, kunciphisa ingozi yokuvala isihlungi nokuqinisekisa ukomiswa okufanayo.

Ukukhetha phakathi kwalezi zindawo kuncike ekusetheni ukukhiqiza okukhethekile kanye nezidingo zenqubo. Isibonelo, izikhungo ezinezinqubo eziyinkimbinkimbi zokuhlanganisa zingase zibeke phambili ukuqapha ngaphambi kwesitoreji, kuyilapho lezo ezigxile ekusebenzeni kahle kokuhlunga zingakhetha ukufakwa ngemva kokwelashwa.

Ukukhetha i-Appropriate Density Meter

Lapho bekhetha imonitha ye-titanium dioxide density, abakhiqizi kufanele bacabangele izici ezinjengokunemba, ukuqina, kanye nezidingo zokunakekelwa. Amamitha wamashubhu adlidlizayo alungele izidingo ezinembayo ephezulu, kuyilapho izinzwa ze-ultrasonic zifanelana nezinhlelo zokusebenza ezingahlaseli. Amamitha e-Coriolis angcono kakhulu ezikhungweni ezidinga ukuminyana kanye nezilinganiso zokugeleza kanyekanye. Ukwengeza, qinisekisa ukuthi idivayisi iyahambisana nemvelo elimazayo yokumiswa kwe-TiO2, ngezinto ezifana nezinzwa ze-ceramic zamamodeli asebenza kahle kakhulu ukuvikela ukuguga.

Ukuhlanganisa ne-Process Control Systems

Ukuze ukwandise izinzuzo zokuqapha ukuminyana okusemgqeni, hlanganisa imitha yokuminyana kwe-titanium dioxide nezinhlelo ezikhona zokulawula inqubo. Lokhu kuvumela ukulungiswa okuzenzakalelayo okusekelwe kudatha yesikhathi sangempela, ukunciphisa ukungenelela okwenziwa ngesandla kanye nokuthuthukisa ukusebenza kahle. Isibonelo, ukuxhuma inzwa yokuminyana kusilawuli se-programmable logic (PLC) kunika amandla ukulungiswa okugxilile okuguquguqukayo, okuqinisekisa ikhwalithi yomkhiqizo engaguquki kuwo wonke umjikelezo wokukhiqiza.

Imibuzo Evame Ukubuzwa

Ungayilawula kanjani i-Inline Concentration ye-Titanium Dioxide Solution?

Ukulawula ukugxila okusemgqeni kwesisombululo se-titanium dioxide kudinga ukuqapha okuthembekile kwe-titanium dioxide. Amadivayisi afana neshubhu elidlidlizayo noma amamitha we-ultrasonic density ahlinzeka ngedatha yesikhathi sangempela, evumela opharetha ukuthi balungise imingcele efana nokuqukethwe kwamanzi noma ukugxilisa ingqondo okuqinile. Ngokuhlanganisa lawa mamitha nezinhlelo zokulawula ezizenzakalelayo, abakhiqizi bangagcina amazinga aphezulu okuminyana, baqinisekise ikhwalithi yomkhiqizo engaguquki kanye nokunciphisa udoti.

Yiziphi Izinzuzo Zokusebenzisa inzwa ye-Titanium Dioxide Density?

Inzwa ye-titanium dioxide density inikezela ngezinzuzo eziningi, okuhlanganisa ukugada kwesikhathi sangempela, ukunemba okuphezulu, nokuqina ezindaweni ezilimazayo. Lezi zinzwa zinciphisa amaphutha esampula okwenziwa ngesandla, izindleko zokusebenza eziphansi, futhi zithuthukisa ikhwalithi yomkhiqizo ngokuqinisekisa ukuminyana okungaguquki phakathi nokwelashwa kwangemva kokwelashwa. Idizayini yabo yokunakekelwa okuphansi ibuye inciphise isikhathi sokuphumula, ibenze babe yisixazululo esingabizi kakhulu kubakhiqizi be-TiO2.

Iluphi uhlobo lwe-Density Meter Olungcono Kakhulu Emkhiqizweni we-TiO2?

Imitha engcono kakhulu ye-titanium dioxide density incike ekusetshenzisweni okuqondile. Amamitha wamashubhu adlidlizayo anikeza ukunemba okuphezulu kwezinqubo ezibucayi, izinzwa ze-ultrasonic zilungele ukuqapha okungahlaseli, futhi amamitha we-Coriolis ahlinzeka ngokuminyana okukabili nokukalwa kokugeleza. Abakhiqizi kufanele bahlole izidingo zabo zenqubo, njengosayizi wepayipi nezici zokumiswa, ukuze bakhethe idivayisi efanelekile kakhulu.

Ukuqapha ukuminyana okusemgqeni kuyashintsha umdlalo kubakhiqizi be-TiO2 abahlose ukuthuthukisa izinqubo zabo zangemuva kokwelashwa. Ngokusebenzisa imitha ye-titanium dioxide density, inzwa ye-titanium dioxide density, noma i-titanium dioxide density monitor, abakhiqizi bangaqinisekisa ikhwalithi engaguquki, banciphise izindleko, futhi bathuthukise ukusebenza kahle kokukhiqiza. Lawa mathuluzi ahlinzeka ngemininingwane yesikhathi sangempela ekumineni kwesixazululo se-titanium dioxide, okuvumela ukulawula okunembayo ezigabeni ezibucayi njengokumboza phezulu nokuhlunga.

Kubakhiqizi abafuna ukuhlala bencintisana, ukutshala imali ezisombululweni zokuqapha ukuminyana okuthuthukile kuyisinyathelo esinamasu. Xhumana nathi namuhla ukuze uhlole ukuthi izinhlelo zethu zokuqapha ukuminyana zingayiguqula kanjani inqubo yakho yokukhiqiza ye-TiO2 futhi zithuthukise imiphumela elinganisekayo.

Isikhathi sokuthumela: Jun-27-2025